Supply OEM Hot Sale Highway Guardrail Roll Forming Machine

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we’ve earned an outstanding track record amongst our consumers across the whole world for Supply OEM Hot Sale Highway Guardrail Roll Forming Machine, We focus on to make exceptional excellent products and solutions to provide assistance for our purchasers to determine long-term win-win partnership.

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we’ve earned an outstanding track record amongst our consumers across the whole world for China Hot Sale Highway Guardrail Roll Forming Machine and Highway Guardrail Roll Forming Machine, Our Company has expert engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the merchandise, Remember to feel free to contact us.

MAIN TECHNICAL PARAMETERS

Material: Galvanized Sheet

Yield strength of raw materials: 235Mpa

Coil Outer Diameter: ≤Ф1200 mm

Coil Inner Diameter: Ф508mm

Steel Strip Width: ≤150mm

Steel Strip Thickness: 2mm

Coil Weight: ≤2000 kg

Machine Floor Area: 25000X3000X1800

PRODUCTION PROCESS

The production line is carried out according to the following process::

Uncoiling→Leveling Servo Feeding→Punching→Cold Roll Forming→Hydraulic Shearing→Material Discharging

MAIN COMPONENTS

1. Uncoiler 1set

Allowable coil inner diameter: Ф508

Max. allowable coil outer diameter: Ф1200mm

Max. allowable roll width: 200 mm

Max. roll carrying weight: ≤2000 kg

2. Servo Feeding 1 set

Maximum feeding speed: 30m/min

Maximum allowable feeding width: ≤200mm

Allowed feeding thickness ≤ 2mm

Single feeding error: ≤±0.2mm (the tolerance is not cumulative)

Servo motor brand: Yaskawa (YASKAWA, Japanese)

Servo motor power: ≈3Kw (subject to the final design)

3. Punching Machine 1set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching distance is adjustable in the transverse direction of the plate, and the punching step can be changed through the electrical control system.

4. Roller Forming Machine 1 set

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Forming pass: 12 passes

Shaft diameter of forming machine: φ60mm (subject to final design)

Motor power: about 30kW (subject to the final design)

Maximum linear speed: 3~10m/min

5. Pneumatic follow-up shearing 1 set

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

6. Hydraulic System 1 set

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic oil tank, etc.The hydraulic system uses a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

MAIN ELECTRICAL COMPONENTS

| No | Items Name | Brand |

| 1 | PLC | Mitsubishi, Japan |

| 2 | Servo Motor | Yaskawa, Japan |

| 3 | Inverter | Delta (Taiwan, China) |

| 4 | Touch screen | Vinylon (Taiwan, China) |

| 5 | Low-voltage electrical components | Omron |

WORKPIECE SAMPLES

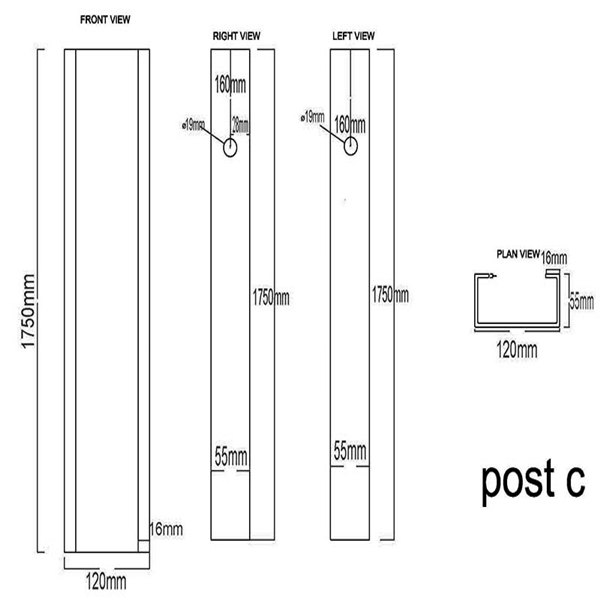

Expressway guardrail C-pillar forming machine is a special equipment for manufacturing expressway guardrail C-pillar. It has been specifically designed to form the desired C-pillar profile and dimensions by feeding a coil of metal through a series of rollers that gradually mold the metal into the desired shape.

A roll forming machine typically consists of a set of rollers or forming stations that apply pressure and gradually shape metal into a C-profile. The machine may also have additional workstations for cutting, punching and performing other operations necessary to complete the posts. The process begins by feeding a continuous coil of metal into a rolling mill.

The metal is then passed through a series of rollers, which gradually shape it into a C-shaped profile to the desired dimensions and features. Once the metal is formed, it is cut to the desired length and any necessary holes or slots are punched in the posts.

The finished C-pillars produced by the roll forming machine are then used in highway barrier installations to provide structural support and protection.