Professional China Color Steel PPGI Rectangular Rain Downpipe Downspout Pipe High Speed Roll Forming Machine

Our organization insists all along the quality policy of “product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff” as well as the consistent purpose of “reputation 1st, purchaser first” for Professional China Color Steel PPGI Rectangular Rain Downpipe Downspout Pipe High Speed Roll Forming Machine, In a word, when you choose us, you choose a best life. Welcome to go to our manufacturing facility and welcome your get! For further more inquiries, you should do not hesitate to get hold of us.

Our organization insists all along the quality policy of “product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff” as well as the consistent purpose of “reputation 1st, purchaser first” for China Roll Forming Machine and Downspout, With the spirit of “high quality is our company’s life; good reputation is our root”, we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

PRODUCT DESCRIPTION

Downspout roll forming production line is made of colored steel or aluminum plate through roller pressing, closed molding, through bending with equipment, shrinkage molding, simple design, simple installation, widely used in modern villas and multi-storey buildings.

MAIN TECHNICAL PARAMETERS

Material: Galvanized Steel

Material thickness: 0.5~0.6mm

Percentage of elongation: ≥2%

Yield strength of material: 550MPa

Material tensile strength: 450 MPa

Coil weight: ≤4ton

Coil ID: 508mm

Coil width: ≤550mm

MAIN COMPOSITIONS

1. UNCOILER.

The uncoiler is a simple manual uncoiler for supporting the material

2. ROLL FORMING MACHINE.

Used to roll the required finished plate shape to the final required cross-sectional shape through the roll forming process.

Main Parameters:

Main machine length: 11600mm×1100mm×1300mm

Feeding device: Feed platform and adjustable guide device

Transmission: chain wheel/gear

Forming rollers tunnel: 21 dots

Rollers material: 45# steelHard Chrome Plating

Shaft diameter: ф75mmhigh precision machining

Forming speed: aprox.15m/min.

Main Motor: aprox.11KW Planetary cycloidal reducer

1. SAW BLADE CUTTING.

It is to cut the formed parts to length

Main Parameter:

Mainly composed of shearing frame, cutting die, hydraulic system, base.

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

Cutting method: stop cutting

Oil pump motor: aprox.4KW

fixed-length accuracy: ±1mm

1. ELECTRICAL CONTROL UNIT.

The whole line adopts the man-machine control mode combining PLC and touch screen. The specification parameters, quantity and system parameters of the parts can be set through the touch screen.

2. HYDRAULIC STATION.

Adopt the combination structure of pump and accumulator, fast blanking and shearing speed, improve the speed of production line.The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank

Hydraulic station: 15kw

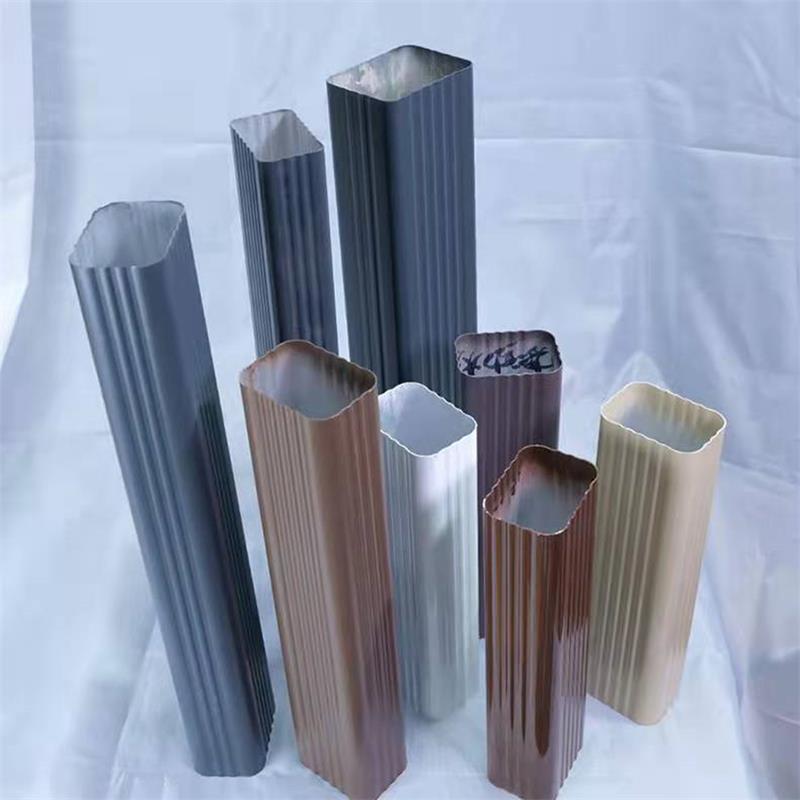

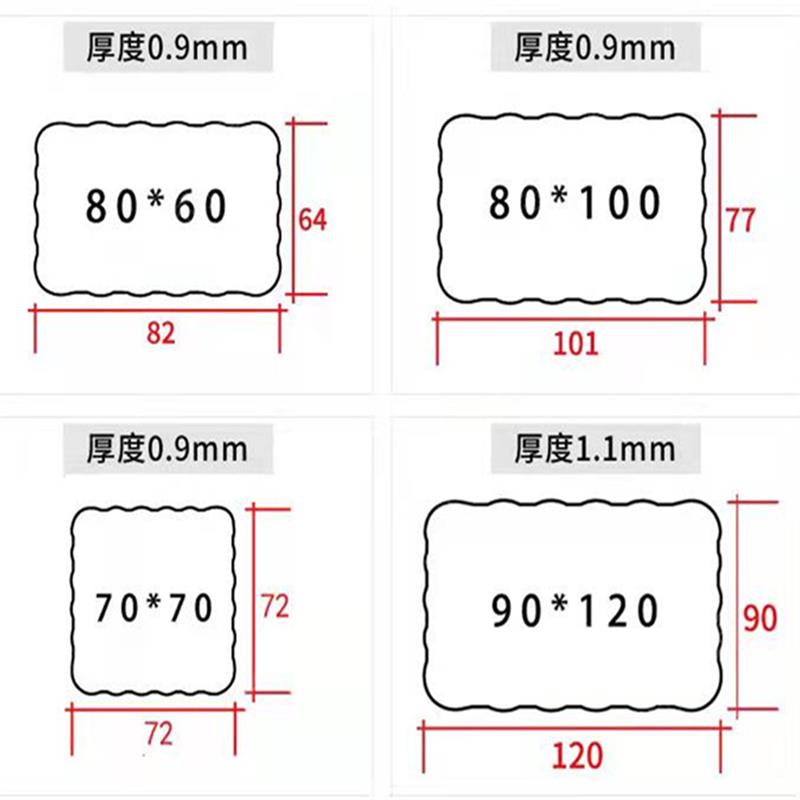

FINISHED SQUARE DOWNSPOUT SHOW

Rain gutter roll forming machine; downpipe roll forming machine; downspout making equipment;rain gutter making machine.

The rainwater pipe forming machine is a kind of equipment used in the production process of rainwater pipes. This machine is used to manufacture rainwater downpipes of different shapes and sizes for use in buildings and structures to direct rainwater away from roofs.

The function of the machine is to bend and shape sheet metal into the desired shape using a series of rollers and dies. Sheet metal is usually made of galvanized steel, aluminum, copper or other materials. This machine can produce rainwater pipes of different lengths and thicknesses.

Rainwater downpipe roll forming machines are durable, reliable and efficient. They can be operated manually or automatically, depending on the complexity of the design. Some of the features of a typical rainwater downpipe roll forming machine include adjustable speed control, automatic cutting and stacking, and the ability to create stormwater pipes in different shapes and styles.

Overall, this machine is an important tool for the construction industry as it helps to produce high-quality stormwater pipes that can withstand varying weather conditions, thereby promoting safety and well-being.