One of Hottest for Purlin Roller Former C U Z Shape Roll Forming Machine

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for One of Hottest for Purlin Roller Former C U Z Shape Roll Forming Machine, Our Company Core Principle: The prestige first ;The quality guarantee ;The customer are supreme.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for China Machine and Purlin Roll Forming Machine, Since always, we adhering to the “open and fair, share to get, the pursuit of excellence, and creation of value”values, adhere to the”integrity and efficient, trade-oriented, best way , best valve” business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

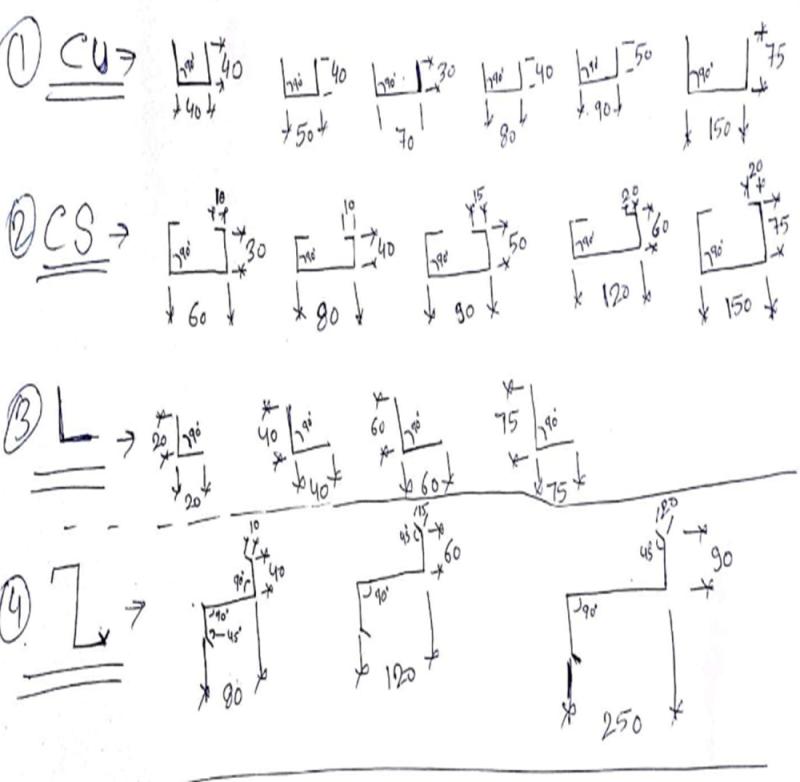

MAIN TECHNICAL PARAMETERS

|

Profile |

Web |

Flange |

Lip |

Thickness |

|

C |

80-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

|

Z |

120-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

Fast Changing Structure

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Material Storage) → Servo Feeding → Multi-Station Punching Machine (Cutting Off) → Roll Forming Machine → Finished Products

MAIN COMPONENTS

This production line is mainly composed by following parts:

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coils ID: Ф508mm; Coil OD : Ф1200mm; Coil Width : 500mm; Coil weight: ≤5000 kg; |

| 2 | Leveling Machine | 5 roller leveling; Max. speed: 20m/min; Max. Leveling width: 500mm; Max. Coil thickness: 1~3mm; Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed: 30m/min; Maximum feed width: ≤500mm; Allowed feed thickness: ≤3mm; Precision of feeding: ±0.2mm/step; Servo motor: Japan, Yaskawa; Servo Motor Power: aprox.4.4KW (according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine | There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13Quotation documents; Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50; Parameters: Forming passes: 36 passes (subject to the final design); Archway sorties: 36+32=68 sorties; Shaft diameter of forming machine: φ70mm (subject to final design); Motor power: 55kw; Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade materialBlade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy: ±1.5mmAccuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan); Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

WORKPIECE SAMPLES OF TILE MAKING MACHINE

CZ quick change roll forming machine line; CZUL fast change roll forming machine; c purlin fast change roll forming machine; CZ Purlin Roll Forming Machine

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for One of Hottest for Purlin Roller Former C U Z Shape Roll Forming Machine, Our Company Core Principle: The prestige first ;The quality guarantee ;The customer are supreme.

One of Hottest for China Machine and Purlin Roll Forming Machine, Since always, we adhering to the “open and fair, share to get, the pursuit of excellence, and creation of value”values, adhere to the”integrity and efficient, trade-oriented, best way , best valve” business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.