One of Hottest for Galvanized Floor Decking Roll Forming Machine/Steel Making Machines on Sale

Our solutions are commonly regarded and trusted by users and can fulfill continuously developing financial and social demands for One of Hottest for Galvanized Floor Decking Roll Forming Machine/Steel Making Machines on Sale, We also ensure that your selection will be crafted with the highest quality and reliability. Please feel free to contact us for further information.

Our solutions are commonly regarded and trusted by users and can fulfill continuously developing financial and social demands for China Galvanized Floor Decking Roll Forming Machine and Floor Decking Steel Making Machines for Sale, We give good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We are going to produce the goods according to your request. If you are interested in any items we offer you, you should feel free to contact us directly by mail, fax, telephone or internet. We’ve been here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

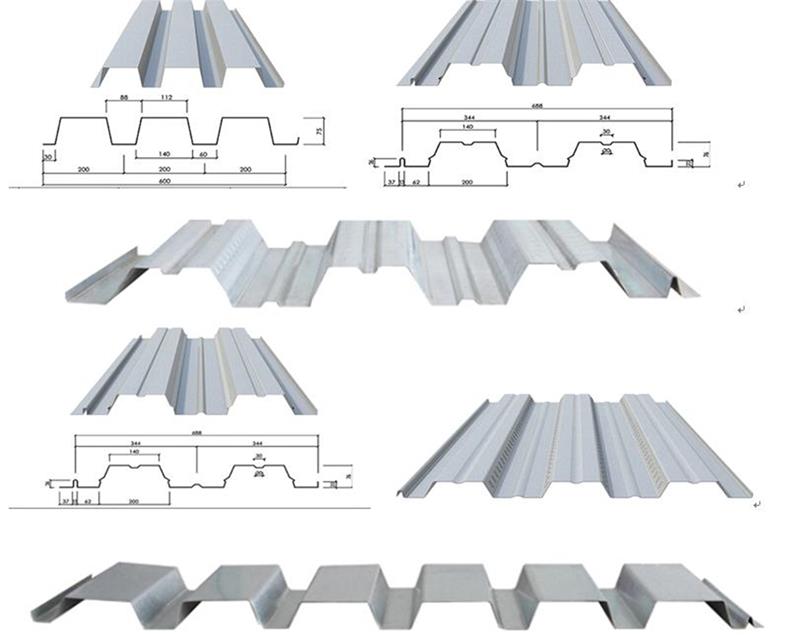

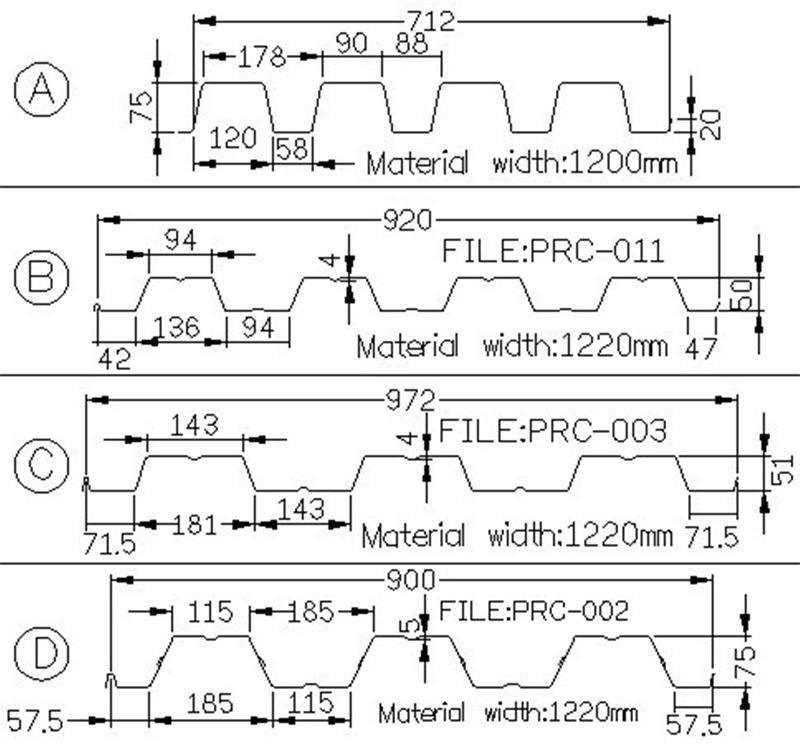

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

A floor roll forming machine is a machine used to produce sheet metal for use as flooring systems for construction projects.

This machine uses a continuous bending process to form metal coils into profiles for flooring applications. The machine usually consists of several components, including an uncoiler (to hold and feed the metal coil), a leveler (to flatten the metal coil) and a roll former (to form the metal into the desired profile ).

The machine can be customized to the specific requirements of a construction project to produce slabs of different shapes and sizes. The end product of a floor roll forming machine is a strong, durable and easy-to-install sheet metal.

This type of flooring system is commonly used in commercial and industrial buildings as well as residential construction projects.