OEM Customized Top Sponsor Listing Wall Panel Metal Steel Floor Deck Roll Forming machinery

We pursue the management tenet of “Quality is remarkable, Company is supreme, Name is first”, and will sincerely create and share success with all clientele for OEM Customized Top Sponsor Listing Wall Panel Metal Steel Floor Deck Roll Forming machinery, We warmly welcome enterprise partners from all walks of daily life, be expecting to establish helpful and cooperative enterprise contact along with you and accomplish a win-win aim.

We pursue the management tenet of “Quality is remarkable, Company is supreme, Name is first”, and will sincerely create and share success with all clientele for China Metal Deck Roll Forming Machine and Metal Deck Forming Machine, Actually need to any of those goods be of interest to you, you should let us know. We are going to be pleased to offer you a quotation on receipt of one’s thorough specs. We have our private expert R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

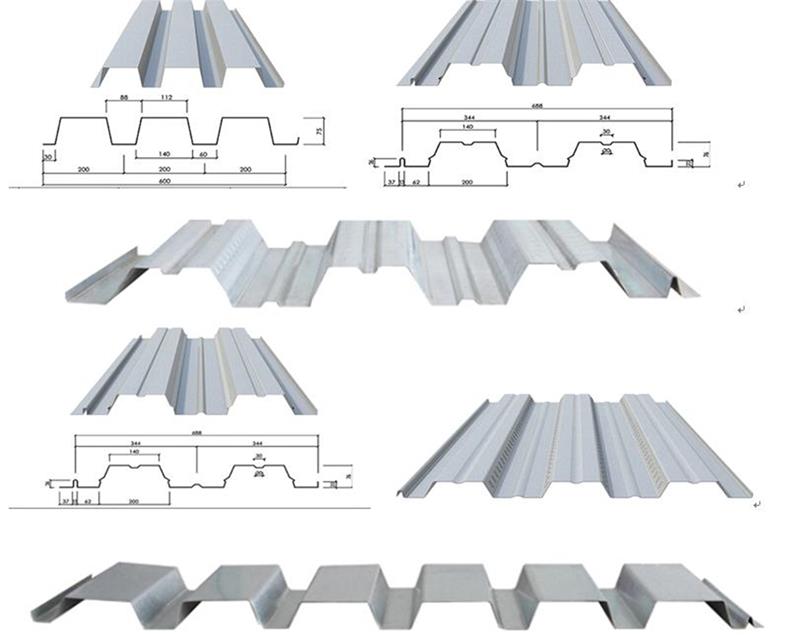

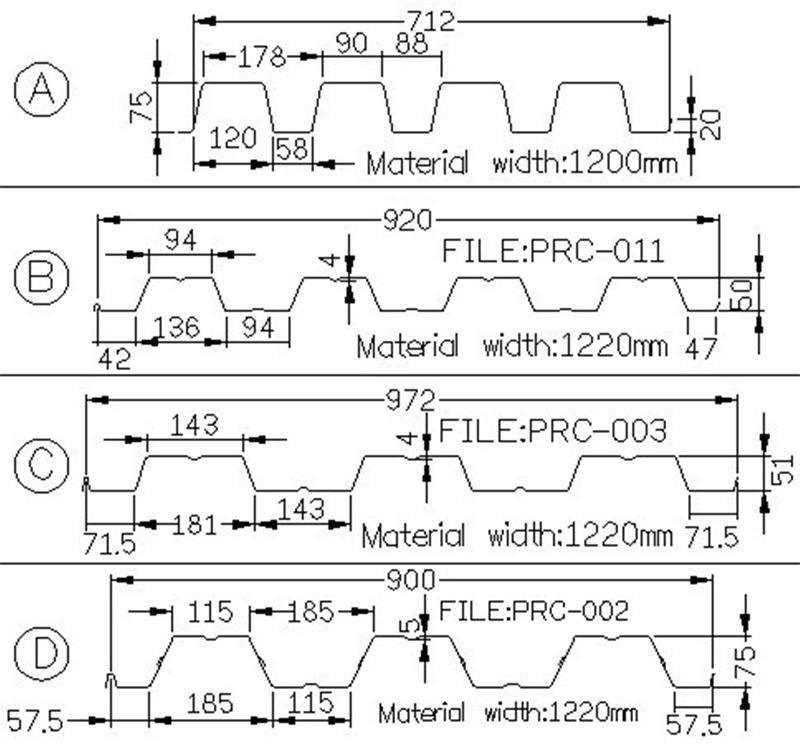

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

The floor deck roll forming machine is a special machine for the production of floor decks. It is commonly used in the construction industry to create durable and cost-effective flooring solutions. The machine uses the roll forming process, which feeds coiled steel through a series of rollers. These rollers gradually shape the steel into the desired profile of the floor panels.

Depending on the design and requirements, the machine may have multiple sets of rollers to create different profiles. A floor roll forming machine typically consists of the following components: an uncoiler to hold the coil, a leveling unit to ensure the steel is flat, a punching unit to punch holes where required and to cut the panels to length cutting device. It may also include control systems for monitoring and adjusting machine parameters. After a roll forming process, the flat steel is transformed into solid floor panels with ribbed or corrugated profiles. These panels are then used as structural components in building construction, providing support and stability to the floors.

Overall, floor roll forming machines play a vital role in the manufacturing process of floor panels, helping to simplify and automate the production process.