New Fashion Design for 1000mm Wall Panel Roofing Panel Color Steel Plate Roll Forming Machine

To continually improve the management procedure by virtue in the rule of “sincerely, great religion and good quality are the base of company development”, we commonly absorb the essence of associated products and solutions internationally, and regularly build new solutions to meet the calls for of consumers for New Fashion Design for 1000mm Wall Panel Roofing Panel Color Steel Plate Roll Forming Machine, We believe that in high-quality in excess of quantity. Before export in the hair there is strict quality control check during treatment as per international top quality standards.

To continually improve the management procedure by virtue in the rule of “sincerely, great religion and good quality are the base of company development”, we commonly absorb the essence of associated products and solutions internationally, and regularly build new solutions to meet the calls for of consumers for China Roll Froming Machine and Forming Machine, Now we have the best products and solutions and qualified sales and technical team.With the development of our company, we have been able to provide customers best products, good technical support, perfect after-sales service.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

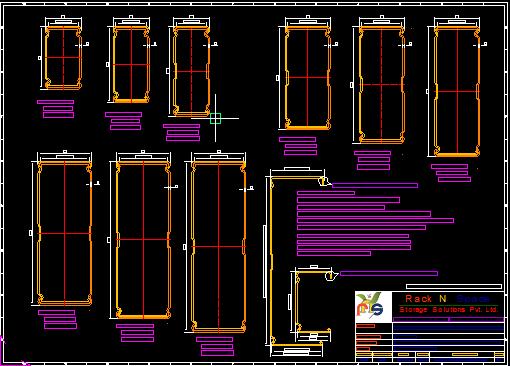

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

A storage rack beam roll forming machine is a machine used to manufacture steel beams for shelving units. These machines are used in fabrication facilities and can produce beams of various lengths and thicknesses to meet specific storage needs.

The process involves feeding the coil of steel through a series of rollers that shape it into the desired beam profile. Once the beam is formed, it is cut to the desired length and can be further processed for additional features or coatings.

The resulting beams are robust and suitable for a variety of industrial and commercial storage environments.