IOS Certificate High Speed 2/3 Waves Highway Fence Guardrail Roll Forming Machine

The company keeps to the operation concept “scientific management, high quality and efficiency primacy, customer supreme for IOS Certificate High Speed 2/3 Waves Highway Fence Guardrail Roll Forming Machine, We’re seeking forwards to establishing long-term business enterprise associations with globally shoppers.

The company keeps to the operation concept “scientific management, high quality and efficiency primacy, customer supreme for China Highway Fence Guardrail Roll Forming Machine and Crash Barrier Roll Forming Machine, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent for you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

MAIN TECHNICAL PARAMETERS

Material: Galvanized Sheet

Yield strength of raw materials: 235Mpa

Coil Outer Diameter: ≤Ф1200 mm

Coil Inner Diameter: Ф508mm

Steel Strip Width: ≤150mm

Steel Strip Thickness: 2mm

Coil Weight: ≤2000 kg

Machine Floor Area: 25000X3000X1800

PRODUCTION PROCESS

The production line is carried out according to the following process::

Uncoiling→Leveling Servo Feeding→Punching→Cold Roll Forming→Hydraulic Shearing→Material Discharging

MAIN COMPONENTS

1. Uncoiler 1set

Allowable coil inner diameter: Ф508

Max. allowable coil outer diameter: Ф1200mm

Max. allowable roll width: 200 mm

Max. roll carrying weight: ≤2000 kg

2. Servo Feeding 1 set

Maximum feeding speed: 30m/min

Maximum allowable feeding width: ≤200mm

Allowed feeding thickness ≤ 2mm

Single feeding error: ≤±0.2mm (the tolerance is not cumulative)

Servo motor brand: Yaskawa (YASKAWA, Japanese)

Servo motor power: ≈3Kw (subject to the final design)

3. Punching Machine 1set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching distance is adjustable in the transverse direction of the plate, and the punching step can be changed through the electrical control system.

4. Roller Forming Machine 1 set

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Forming pass: 12 passes

Shaft diameter of forming machine: φ60mm (subject to final design)

Motor power: about 30kW (subject to the final design)

Maximum linear speed: 3~10m/min

5. Pneumatic follow-up shearing 1 set

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

6. Hydraulic System 1 set

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic oil tank, etc.The hydraulic system uses a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

MAIN ELECTRICAL COMPONENTS

| No | Items Name | Brand |

| 1 | PLC | Mitsubishi, Japan |

| 2 | Servo Motor | Yaskawa, Japan |

| 3 | Inverter | Delta (Taiwan, China) |

| 4 | Touch screen | Vinylon (Taiwan, China) |

| 5 | Low-voltage electrical components | Omron |

WORKPIECE SAMPLES

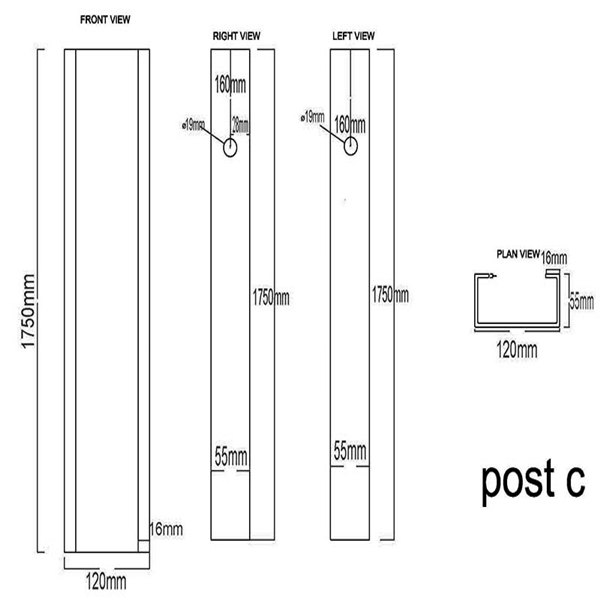

C-profile forming machine for highway guardrail is a special equipment for manufacturing C-shaped profiles for highway guardrail. These profiles are an important component in providing safety and protection for vehicles traveling on the highway.

A roll forming machine consists of a series of rollers that progressively form a continuous metal strip into the desired C-shaped profile. The machine can control and adjust the width, height and thickness of profiles according to specific requirements.

The process begins by feeding a roll of metal strip into the machine, which is then passed through a series of rollers, which gradually bend and shape the metal strip into a C-profile. During this process, rollers apply pressure to ensure that the profile retains its shape and size. Roll forming machines are usually automated and can run at high speeds to efficiently produce highway guardrail profiles. It is designed for continuous production and has safety features to ensure the health of the operator.

Overall, the highway guardrail C profile forming machine plays a vital role in the manufacturing process of highway guardrail, which can efficiently and accurately produce the C profiles required for the safety and protection of vehicles on the road.