High definition China Professional Manufacturer of Tile Roll Forming Machine

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for High definition China Professional Manufacturer of Tile Roll Forming Machine, Welcome to setup long-term romantic relationship with us. Best Value Permanently Top quality in China.

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for China Tile Roll Forming Machine, Roll Forming Machine, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Yield strength of raw materials | 235Mpa |

| Tensile strength of raw materials | ≤550Mpa |

| Coil outer diameter | ≤Ф1600 mm |

| Inner diameter of coil | Ф508mm |

| Strip thickness | 2.3~3mm |

| Single roll weight | ≤7000 kg |

PRODUCTION PROCESS

The Production Line Is Carried Out According To The Following Process:

Uncoiler → Looper (Storage) → Servo Feeding → Punching Machine → Roller Forming → Shearing → Automatic Palletizing Of Finished Products

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Material Storage Device

The storage device is composed of two parts: the arc-shaped roller and the supporting device. There are four groups of arc-shaped rollers. Between the two storage bins, they are composed of an arc frame and a single rotating roller. A photoelectric switch is installed in the pit of the silo to control the position of the roll entering the pit, so that the speed of each working part can be perfectly matched.

3. Leveling Servo Feeder

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick. The feeding accuracy is accurate without accumulated tolerance.

4. Pneumatic follow-up shearing

It cuts the formed parts to a fixed length. The whole working process does not need to stop the whole line, and it automatically tracks and cuts, which is fast and efficient

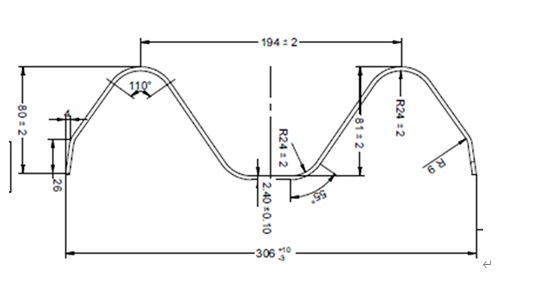

WORKPIECE SAMPLES

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for High definition China Professional Manufacturer of Tile Roll Forming Machine, Welcome to setup long-term romantic relationship with us. Best Value Permanently Top quality in China.

High definition China Tile Roll Forming Machine, Roll Forming Machine, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.