Cheap PriceList for Zk Highway W Beam Guardrail Roll Forming Machine with ISO 9001 Quality Certificate

Our company aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine continuously for Cheap PriceList for Zk Highway W Beam Guardrail Roll Forming Machine with ISO 9001 Quality Certificate, We fully welcome consumers from everywhere in the world to establish stable and mutually helpful small business associations, to have a vibrant future alongside one another.

Our company aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine continuously for China Roll Forming Machine and Roll Form Machine, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of “Quality First, Customer Paramount, Sincerity and Innovation” in our mind, We have now achieved great progress in the past years. Clients are welcomed to buy our standard items, or send us requests. You are going to be impressed by our quality and price. You should contact us now!

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Server system | YASKAWA |

| Steel belt width | ≤750mm |

| Production line speed | 15m/min |

| Electric control unit | PLC(Mitsubishi) |

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Uncoiler Parameter

| Allowable coil inner diameter | Ф508mm |

| Maximum allowable roll diameter | Ф1600mm |

| Maximum allowable roll width | 500 mm |

| Maximum roll carrying weight | ≤5000 kg |

| Uncoiler motor power | ≈5.5Kw (subject to the final design) |

3. Leveling Servo Feeder

The front of the leveling machine is also equipped with a telescopic shovel head and a material pressing device to ensure that the raw material rolls enter the leveling machine smoothly and safely.

| Maximum working speed | 40 m/min |

| Maximum leveling roll width | 500mm |

| Adapt to the maximum roll thickness | 2mm |

| Motor power of leveling machine: | ≈7.5Kw(subject to the final drawing design) |

4. Roller Forming Machine

The forming unit adopts an independent frame (housing mode). Motor, reducer drive, gear and chain drive.

| Forming Passes | about 13 |

| Shaft diameter of forming machine | φ80mm(subject to the final design) |

| Motor Power | about 55W(subject to the final design |

| Max. speed | 10~15m/min |

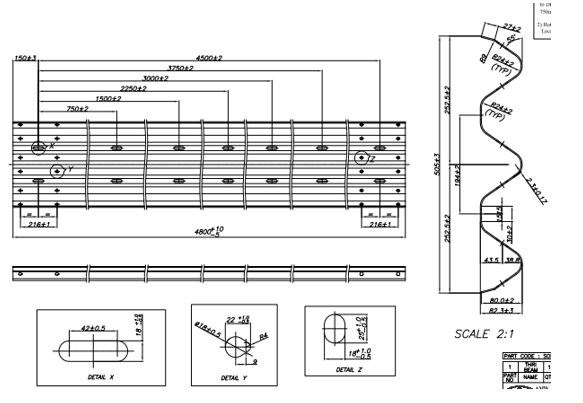

WORKPIECE SAMPLES

This is a 3 wave barrier made by our production equipment.

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection.

The expressway guardrail beam forming machine is a special equipment for the manufacture of expressway guardrail beams. It is designed to produce these beams accurately and efficiently by rolling metal coils into the desired shape.

The machine consists of several components including uncoiler, leveling unit, roll forming station, cutting mechanism and control system. The process begins by loading the metal coil onto an uncoiler, which feeds it into a leveling unit. The leveling device eliminates any coil memory and ensures that the metal is flat and uniform. The flat metal strip then passes through a series of roll forming stations where it is gradually formed into the desired guardrail beam profile.

Each roll forming station applies pressure and bends the metal, gradually shaping it into the desired shape. The number of roll forming stations can vary depending on the complexity of the guardrail beam design. After the beam profile is formed, the cutting mechanism trims excess material and cuts the beam to the desired length. The control system regulates the movement of the machine and ensures precise measuring and cutting. Highway Guardrail Beam Roll Forming Machines are designed for high production rates to produce consistent high quality guardrail beams. They offer advantages such as high efficiency, cost-effectiveness, and the ability to produce a variety of beam profiles and sizes.

These machines are vital in the manufacture of highway guardrail beams, which play a vital role in roadside safety by protecting vehicles from potential hazards.