CE Certificate Customized Road Safety Protection 2 Wave Crash Barrier Profiles Roll Forming Machine

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for CE Certificate Customized Road Safety Protection 2 Wave Crash Barrier Profiles Roll Forming Machine, By 10 years effort, we attract consumers by aggressive cost and exceptional service. Moreover, it really is our sincere and sincerity, which assistance us always be clients’ first choice.

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for China Road Barrier Machine and Guardrail Machine, We always stick to the tenet of “sincerity, high quality, high efficiency, innovation”. With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our merchandise, and we have been sure that we’ll supply just what you want, as we always believe that your satisfaction is our success.

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Yield strength of raw materials | 235Mpa |

| Tensile strength of raw materials | ≤550Mpa |

| Coil outer diameter | ≤Ф1600 mm |

| Inner diameter of coil | Ф508mm |

| Strip thickness | 2.3~3mm |

| Single roll weight | ≤7000 kg |

PRODUCTION PROCESS

The Production Line Is Carried Out According To The Following Process:

Uncoiler → Looper (Storage) → Servo Feeding → Punching Machine → Roller Forming → Shearing → Automatic Palletizing Of Finished Products

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Material Storage Device

The storage device is composed of two parts: the arc-shaped roller and the supporting device. There are four groups of arc-shaped rollers. Between the two storage bins, they are composed of an arc frame and a single rotating roller. A photoelectric switch is installed in the pit of the silo to control the position of the roll entering the pit, so that the speed of each working part can be perfectly matched.

3. Leveling Servo Feeder

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick. The feeding accuracy is accurate without accumulated tolerance.

4. Pneumatic follow-up shearing

It cuts the formed parts to a fixed length. The whole working process does not need to stop the whole line, and it automatically tracks and cuts, which is fast and efficient

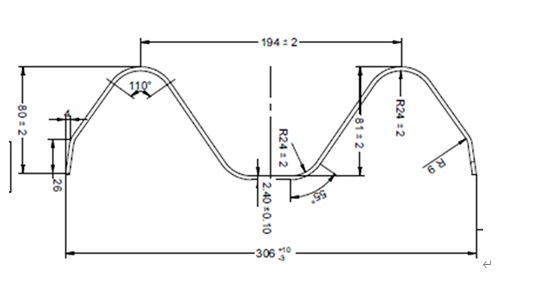

WORKPIECE SAMPLES

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection

Crash barrier molding machine is the equipment used to manufacture crash barriers, which are a safety device installed on roads and highways to prevent vehicles from deviating from the road or colliding with obstacles.

The machine is designed to efficiently produce crash barriers by shaping and forming steel or other materials to the required specifications. It can be operated automatically or manually, depending on the model and manufacturer.

A crash barrier forming machine usually consists of a hydraulic system, a roll forming station, a leveling and cutting system, and a control panel. The hydraulic system provides the necessary force to shape the material, while the roll forming station shapes the material into the desired profile. The leveling and cutting system ensures precise sizing and cutting of the crash barrier. The control panel allows the operator to adjust parameters such as length, width and thickness of the crash barrier. Advanced models may also feature features such as automatic feeding and cutting, further increasing productivity and efficiency.

Overall, the crash barrier forming machine is an indispensable tool in the crash barrier manufacturing process, which can ensure high-quality and standardized production for road safety.