18 Years Factory Highway Board Guardrails Profiles Glazed Sheet Tile Cold Roll Forming Machine Production Line

We are proud of the substantial buyer pleasure and wide acceptance due to our persistent pursuit of top of the range each on solution and repair for 18 Years Factory Highway Board Guardrails Profiles Glazed Sheet Tile Cold Roll Forming Machine Production Line, Our products enjoy good popularity among our customers. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are proud of the substantial buyer pleasure and wide acceptance due to our persistent pursuit of top of the range each on solution and repair for China Cold Roll Forming Machine and Cold Roll Forming, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

PRODUCT DESCRIPTION

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

MAIN PARAMETERS

Material: Galvanized sheet

Yield strength of raw materials: ≤235Mpa

Tensile strength of raw materials: ≤550Mpa

Outer Diameters of Coils: ≤Ф1300 mm

Inner Diameter of Coils: Ф508

Steel strap width: ≤1000mm

Steel Strap Thickness: 0.2~0.4mm

Weight/Coil: ≤5000 kg

PRODUCTION PROCESS

The glazed tiles manufacturing machine products are carried out according to the following process:

Uncoiling → Looper (Storage) → Cold Forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS&SPECIFICATION

| No | Items Name | Specifications |

| 1 | Decoiler | Manual Type; Coils ID: Ф508mm; Coil OD: Ф1300mm; Coil Width: 1000mm; Coil weight: ≤5000 kg |

| 2 | Roll Forming Machine | The forming unit is driven by motor, reducer and sub-reducer. Molding machine memorial arch for independent memorial arch structure (non – plate structure), stable performance, reliable, high precision. The base is welded steel structure. Annealing after welding.The molding roller is designed by professional software, and the material is made of high quality 45 steel and hard chrome plating. Forming passes: 16 passes (subject to the final design); Shaft diameter: φ70mm (subject to final design); Motor power: 5.5kw Maximum linear speed: 2~5 m/min |

| 3 | Hydraulic Cutting | Cutter mode adopts no scrap cutting. Cutter material: Cr12MoV (hardness is HRC58~62 after quenching); Measuring accuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

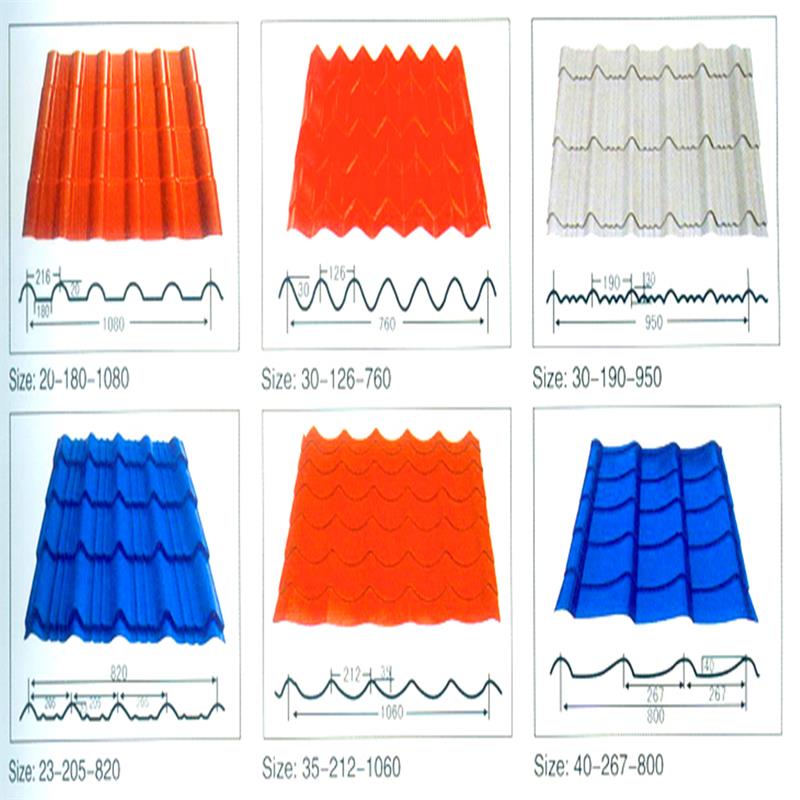

WORKPIECE SAMPLES

Glazed tile roll forming machine;glazed tiles manufacturing machine;glazed tile forming machine

The glazed tile forming machine is the equipment used to produce glazed tiles in the manufacturing industry. It is designed to produce uniform, high-quality glazed tiles. The machine consists of multiple rollers that gradually shape the sheet metal into the desired tile profile. These rollers are adjustable to accommodate tiles of different sizes and designs.

Glazed tile roll forming machines also include an uncoiler for securing the metal coil or sheet that will be fed into the machine. The sheet is then guided through a series of rollers and undergoes various forming processes such as bending, forming and cutting. In addition, the machine is equipped with a glazing device, which can apply a layer of glaze or enamel on the surface of the tiles. This glaze can help enhance the appearance of the tile and provide protection against abrasion, moisture and stains.

Overall, the glazed tile forming machine is an essential tool for glazed tile manufacturers, providing efficient and precise production capabilities.