100% Original Factory Steel Downspout Down-Pipe Gutter Rain Pipe Bending Drain Pipe Roll Forming Machine

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for 100% Original Factory Steel Downspout Down-Pipe Gutter Rain Pipe Bending Drain Pipe Roll Forming Machine, We welcome new and outdated consumers from all walks of existence to speak to us for long run enterprise relationships and acquiring mutual success!

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for China Machine and Rain Gutter, They’re durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it’s a should really to suit your needs personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we’ll have a vibrant prospect and to be distributed all over the world in the years to come.

PRODUCT DESCRIPTION

Downspout roll forming production line is made of colored steel or aluminum plate through roller pressing, closed molding, through bending with equipment, shrinkage molding, simple design, simple installation, widely used in modern villas and multi-storey buildings.

MAIN TECHNICAL PARAMETERS

Material: Galvanized Steel

Material thickness: 0.5~0.6mm

Percentage of elongation: ≥2%

Yield strength of material: 550MPa

Material tensile strength: 450 MPa

Coil weight: ≤4ton

Coil ID: 508mm

Coil width: ≤550mm

MAIN COMPOSITIONS

1. UNCOILER.

The uncoiler is a simple manual uncoiler for supporting the material

2. ROLL FORMING MACHINE.

Used to roll the required finished plate shape to the final required cross-sectional shape through the roll forming process.

Main Parameters:

Main machine length: 11600mm×1100mm×1300mm

Feeding device: Feed platform and adjustable guide device

Transmission: chain wheel/gear

Forming rollers tunnel: 21 dots

Rollers material: 45# steelHard Chrome Plating

Shaft diameter: ф75mmhigh precision machining

Forming speed: aprox.15m/min.

Main Motor: aprox.11KW Planetary cycloidal reducer

1. SAW BLADE CUTTING.

It is to cut the formed parts to length

Main Parameter:

Mainly composed of shearing frame, cutting die, hydraulic system, base.

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

Cutting method: stop cutting

Oil pump motor: aprox.4KW

fixed-length accuracy: ±1mm

1. ELECTRICAL CONTROL UNIT.

The whole line adopts the man-machine control mode combining PLC and touch screen. The specification parameters, quantity and system parameters of the parts can be set through the touch screen.

2. HYDRAULIC STATION.

Adopt the combination structure of pump and accumulator, fast blanking and shearing speed, improve the speed of production line.The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank

Hydraulic station: 15kw

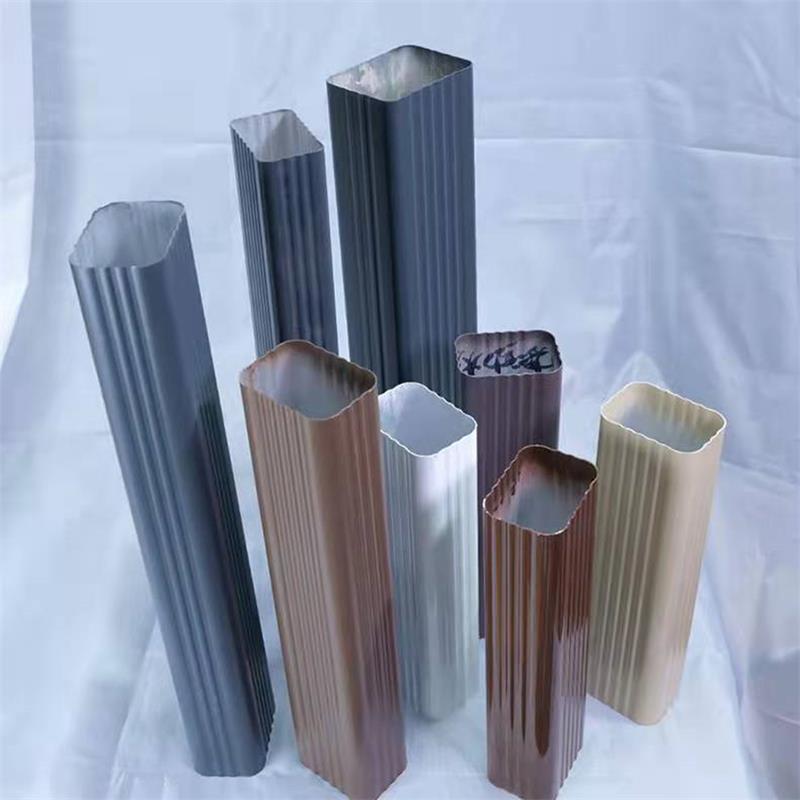

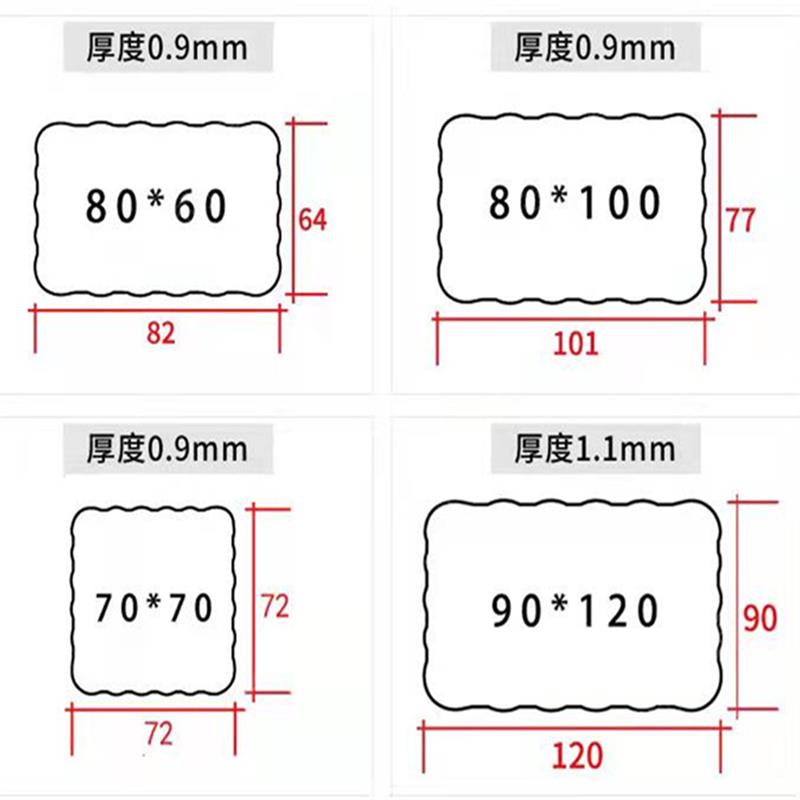

FINISHED SQUARE DOWNSPOUT SHOW

Rain gutter roll forming machine; downpipe roll forming machine; downspout making equipment;rain gutter making machine.

The rainwater pipe forming machine is a special equipment for producing rainwater pipes. It usually consists of a series of rollers and other mechanisms that shape the sheet metal into the desired profile for the downspout.

This machine can process aluminum, steel, copper and other materials according to requirements. Roll forming machines create consistent and precise downspout sections while minimizing waste. It usually includes functions such as cutting mechanism and control system to ensure accurate and efficient production.

Some machines may have additional functions, such as punching holes or embossing patterns on downspouts.

Rain downspout roll forming machines are commonly used in the construction and roofing industries as they provide a cost-effective and reliable way to produce downspouts in large quantities. They can be operated manually or automatically, depending on production volumes and specific requirements of the manufacturer.